A Guide for Beginners-TEPI

TEPI Formwork is an innovative and efficient solution for concrete construction projects. In this beginner’s guide, we will take a closer look at the basics of formwork, including the different types and materials used, and their applications in construction.

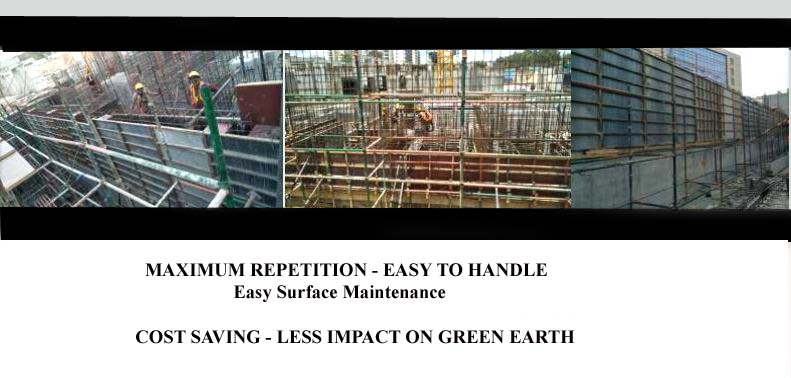

Advantages of TEPI Lightweight Formwork

TEPI Formwork is the future of the construction industry. Our innovative design and technology make us stand out from the rest. We offer cost-effective solutions that are not only affordable but also sustainable.

Achieve Sustainability Goals in Construction

Every parameter like height, width, length, horizontal and vertical load, joinery of formwork play a critical role in the construction process.The formwork must be designed to support the weight of the concrete, resist the pressure of the fresh concrete, and maintain its shape until the concrete sets.

Sustainable Building Practices: Using Recycled Materials in Formwork Design

TEPI FORMWORK is the future of the construction industry. Our innovative design and technology make us stand out from the rest. We offer cost-effective solutions that are not only affordable but also sustainable.

Retaining wall types , benefits and advantages

Retaining Walls: These walls are designed to resist lateral pressure from soil or other materials and retain them in place. They are commonly used to create level platforms on sloped terrain or to prevent soil erosion.

How does TEPI Formwork fair against other types of Formwork?

TEPI FORMWORK is the future of the construction industry. Our innovative design and technology make us stand out from the rest. We offer cost-effective solutions that are not only affordable but also sustainable.

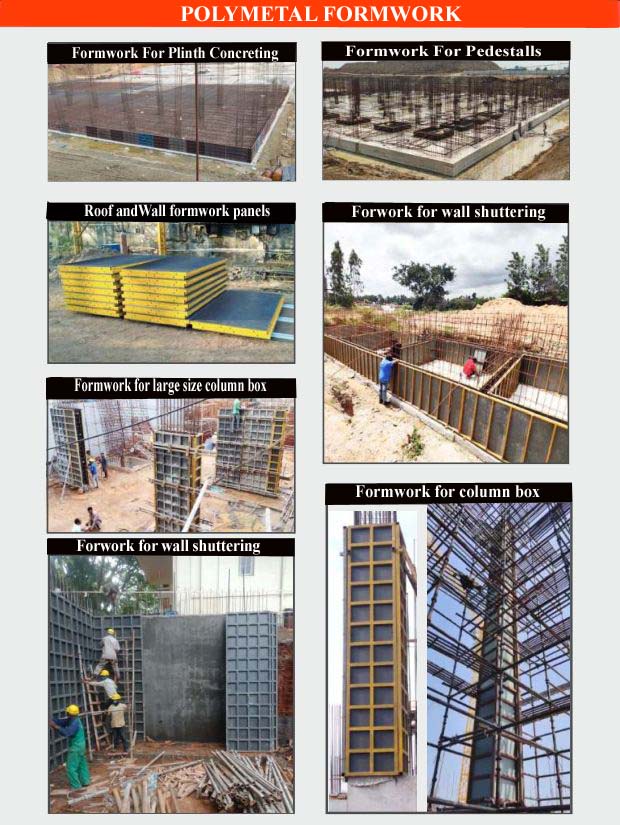

Beam Formwork

Beam formwork is an essential component in the construction industry, providing the temporary mold or framework for shaping and supporting horizontal and vertical concrete beams during the pouring and curing process. Beam formwork ensures that the concrete beams are cast with the desired shape, dimensions, and structural integrity.

Slab Formwork

Slab formwork is a crucial component in the construction industry, providing a temporary mold or framework for shaping and supporting horizontal concrete slabs during the pouring and curing process. It plays a vital role in ensuring the structural integrity, flatness, and finish quality of concrete slabs in various construction projects.

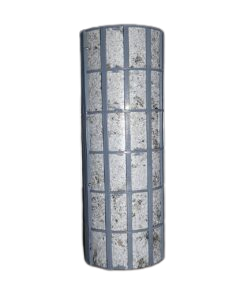

Circular Column Formwork

Circular column formwork is a specialized type of formwork designed to create molds for casting concrete columns with circular or curved shapes. This formwork system is essential in construction projects where architectural designs require the incorporation of cylindrical or rounded columns. The circular column formwork simplifies the process of shaping and molding such elements, offering efficiency, adaptability, and precision in construction. Here’s an in-depth exploration of circular column formwork:

Wall Formwork

Wall formwork is a crucial component in the construction industry, providing a temporary mold or framework for shaping and supporting walls during the concrete pouring and curing process. This formwork system is essential for creating vertical structures, including both exterior and interior walls in buildings. Wall formwork comes in various designs, materials, and configurations, catering to different project requirements. Here’s a comprehensive exploration of wall formwork:

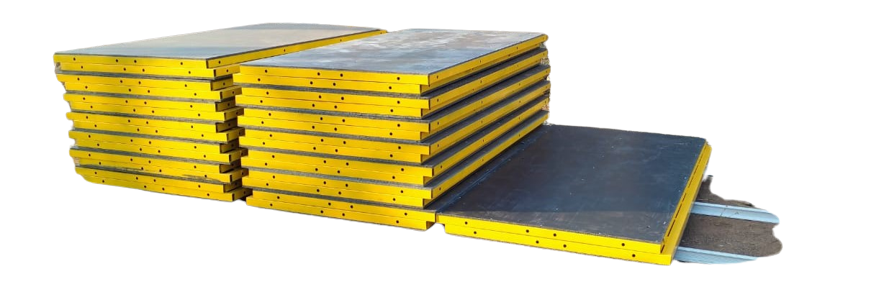

Reusable Plastic Formwork

Reusable plastic formwork represents a significant innovation in the construction industry, providing a sustainable and cost-effective alternative to traditional formwork materials such as wood, steel, and aluminum. This type of formwork is designed to be used multiple times, reducing waste, lowering costs, and contributing to more environmentally friendly construction practices. Here’s an in-depth exploration of reusable plastic formwork:

Plastic formwork products

Plastic formwork products encompass a variety of components and systems designed to facilitate the construction of structures using a lightweight, durable, and versatile material such as high-density polyethylene (HDPE). These products serve as temporary molds into which concrete is poured, shaping the desired structure. The plastic formwork market has seen the development of different types of products to cater to various construction needs. Here are some common types of plastic formwork products:

Monolithic Formwork

Monolithic formwork refers to a construction method where the entire structure, or a significant portion of it, is cast in a single pour of concrete, creating a seamless and integrated structure. In this approach, formwork is used to shape the concrete as it sets, creating a monolithic structure without joints or seams. This method is often employed in various construction projects, offering advantages such as speed, efficiency, and structural integrity

Stair Formwork

Stair formwork is a specialized type of formwork designed for constructing concrete stairs in buildings and other structures. This formwork system provides the necessary framework to mold and shape the concrete used to create staircases. Stair formwork is essential for ensuring that the stairs are structurally sound, dimensionally accurate, and have a smooth finish

Benefits of plastic formwork in residential and commercial projects

Plastic formwork has gained prominence in the construction industry, presenting a range of benefits that make it an appealing choice for both residential and commercial projects. This innovative construction solution, often made from high-density polyethylene (HDPE), offers advantages in terms of cost-effectiveness, versatility, sustainability, ease of use, and overall project efficiency.

Applications of Plastic Formwork in Construction

Plastic formwork has emerged as a transformative technology in the construction industry, revolutionizing traditional formwork methods. This comprehensive discussion explores the diverse applications of plastic formwork, covering its use in residential construction, commercial buildings, infrastructure projects, and other specialized applications.